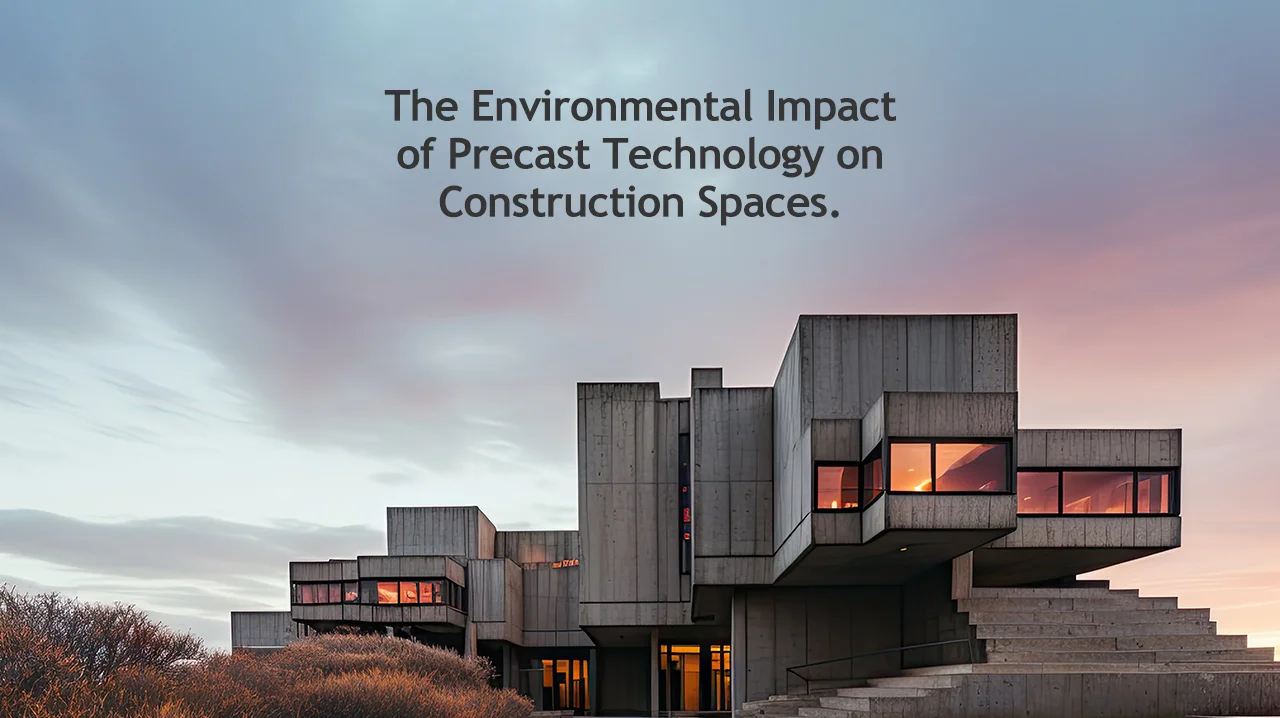

In the ever-evolving landscape of construction technology, Urbanaac Precast Solutions in Gujarat has emerged as a pioneering force, transforming the way we build our spaces. As the demand for sustainable and eco-friendly construction practices rises, the environmental impact of precast technology cannot be overlooked. In this blog, we will delve into the various aspects of how Urbanaac Precast Solution is contributing to a greener and more efficient construction industry.

Reduced Materials Waste

One of the key advantages of using Urbanaac Precast Solutions lies in its ability to minimise materials waste. Traditional construction methods often result in significant wastage of materials due to inaccuracies, rework, and overestimation. However, Urbanaac’s precast elements are manufactured with precision in controlled environments, ensuring minimal waste during the production process.

By utilising cutting-edge technology, Urbanaac Precast Solution minimises the need for excessive on-site adjustments and alterations, further reducing the environmental footprint of construction projects. The meticulous planning and execution of precast elements construction lead to optimised material usage, making it a sustainable choice for environmentally conscious builders.

Transportation Efficiencies

Transportation of construction materials is a major contributor to environmental pollution. Traditional construction methods involve transporting raw materials to the construction site, leading to increased carbon emissions and energy consumption. Urbanaac Precast Solutions revolutionised this aspect of construction by producing precast elements in dedicated manufacturing facilities.

The centralised production of precast elements allows for more efficient transportation logistics. By reducing the distance travelled and streamlining the delivery process, Urbanaac minimises the carbon footprint associated with construction projects. This not only benefits the environment but also contributes to cost savings for builders.

Water Conservation

Water scarcity is a global concern, and sustainable construction practices play a crucial role in addressing this issue. Traditional construction methods often involve the extensive use of water for mixing concrete and curing structures. In contrast, Urbanaac Precast Solutions utilises a dry-cast method that significantly reduces water consumption during production.

The precast manufacturing process at Urbanaac emphasises water conservation without compromising the quality and integrity of the final product. This approach aligns with the growing need for eco-friendly construction solutions that prioritise resource efficiency.

Energy Efficiency

Urbanaac Precast Solutions incorporates advanced technologies to enhance energy efficiency in the construction process. The controlled environment of precast manufacturing facilities allows for optimal energy utilisation compared to on-site construction. The efficient use of energy during production results in a lower overall environmental impact.

Additionally, the durability of precast elements contributes to long-term energy savings in the operational phase of a building. Buildings constructed using Urbanaac Precast Solutions exhibit excellent thermal performance, reducing the need for extensive heating or cooling systems. This energy-efficient attribute aligns with the global push towards sustainable and green building practices.

Also Read: [The Significance of Precast Technology in Shaping the Future of Construction.]

How Precast Technology Enhances Safety:

- Reduced On-Site Activities: Precast technology involves the manufacturing of building components off-site in controlled environments. This minimises the need for extensive on-site construction activities, reducing the potential for accidents and injuries.

- Controlled Environment: Precast manufacturing facilities provide a controlled and safer environment for workers compared to on-site construction. Workers can focus on their tasks without being exposed to the unpredictable conditions of on-site work.

- Precision and Quality: Precast elements are manufactured with precision, ensuring consistent quality. This reduces the likelihood of errors or rework on-site, contributing to a safer and more efficient construction process.

- Less On-Site Material Handling: Precast elements are transported to the construction site after manufacturing. This reduces the need for extensive material handling on-site, minimising the risk of accidents associated with manual lifting and transportation of heavy materials.

- Faster Construction: Precast technology often leads to faster construction timelines. Reduced construction duration means less exposure to potential hazards for workers.

- Environment-Friendly Construction Process:

Precast technology emits less pollution in comparison to its traditional counterparts which aligns perfectly with the strict municipal corporation laws, rules & regulations which makes it a win-win construction approach for the real estate developers. This way, the developers can also avoid paying hefty fines, and ensure eco-friendly construction & timely delivery.

Conclusion

Urbanaac Precast Solutions in Gujarat stands as a beacon of innovation in the construction industry, demonstrating that progress and sustainability can go hand in hand. The reduced materials waste, transportation efficiencies, water conservation, and energy efficiency offered by Urbanaac’s precast technology are shaping the future of construction.

As the demand for sustainable construction practices continues to grow, Urbanaac Precast Solutions emerges as a reliable partner for builders and developers committed to minimising their environmental impact. By embracing this advanced construction technology, the industry can contribute significantly to a greener and more sustainable future. As we move forward, let Urbanaac Precast Solutions be the cornerstone of a construction revolution that benefits both the present and future generations.